- Mon - Fri: 10.00am - 06.00 pm

- SCO-45 Vyapar Sadan Sec - 14 Gurgaon

- sales@anviloytooling.com

T-slot cutter

T-slot cutter

A T-slot cutter generally applies to edge grooving、Keyway grooving、T slot grooving, and some manufacturers use the thick T-Slot cutter for back milling.

Popular T-slot Cutters in machining fields:

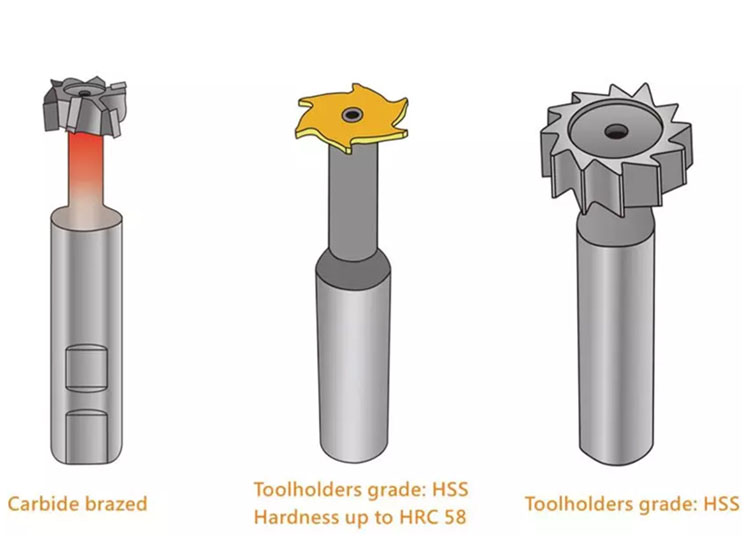

- HSS (High Speed Steel) T-slot cutters: Cheaper price but short life time, lower cutting speed.

- Welding type T-slot cutters: The welding process generates a very high temperature, it will cause the hardness of the shank declined below HRC25 and the tool life, cutting efficiency disappointing. In addition, thin inserts are unable to be welded to the cutter.

- Solid carbide T-slot cutters: Compare with "HSS" and "welding type", it performs a better quality in cutting speed and life time, but the price is relatively higher than above two.

YIH TROUN indexbale T-slot cutter : Tool shareability No.1, same shank fits more than 400 different carbide inserts

Regardless of HSS T-slots、welding type T-slots or solid carbide T-slots, the one drawback those cutters have in common is each individual cutter has their own size and single application, users must throw away the entire cutter when it was damaged.

For example, someday when they get a new project needs a cutter in Ø15mm AE4mm with shank size Ø10mm; if none of their existing cutters fit the requirement, they have no choice but to buy an all-new cutter.